How To Calculate Alminum Electrolytic Capacitors' Life Time?

1-1. Estimation of life with minimal ripple current (negligible).

Generally, the life of an aluminum electrolytic capacitor is closely related with its ambient temperature and the life will be approximately the same as the one obtained by Arrhenius’ equation.

![]()

L: Life at temperature T

Lo: Life at temperature To

The effects to the life by derating of applied voltage etc. are neglected because they are small compared to that by the temperature.

1-2. Estimation of life considering the ripple current.

The ripple current affects the life of a capacitor because the internal loss (ESR) generates heat. The generated heat will be:

P=I2R..................(2)

I: Ripple current (Arms) R: ESR (Ω)

With increase in the temperature of the capacitor:

![]()

ΔT: Temperature increase in the capacitor core (deg.) I: Ripple current (Arms) R: ESR (Ω)

A: Surface area of the capacitor (cm2) H: Radiation coefficient (Approx. 1.5~2.0x10-3W/cm2x°C)

The above equation (3) shows that the temperature of a capacitor increase in proportion to the square of the applied ripple current and ESR, and in inverse proportion to the surface area. Therefore, the amount of the ripple current determines the heat generation, which affects the life. The value of ΔT varies depending on the capacitor types and operating conditions. The usage is generally desirable as ΔT remains less than 10°C for 85°C products and 5°C for 105°C products and higher temperature products.

Since it is actually difficult to measure the temperature increase at the capacitor core. the following table is provided for conversion from the surface temperature increase to the core temperature increase.

Table

Case Diameter | 10 | 12.5~16 | 18 | 22 | 25 | 30 | 35 |

Core/Surface | 1.1 | 1.2 | 1.25 | 1.3 | 1.4 | 1.6 | 1.65 |

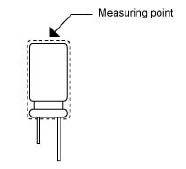

The measuring point for temperature increase due to ripple current is shown below.

Test results:

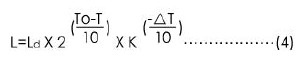

(1) The life equation considering the ambient temperature and the ripple current will be:

Ld: Life at DC operation (h)

K: Ripple acceleration factor (k=2. if within allowable ripple current) (k=4. It exceeding allowable ripple current)

To: Maximum guaranteed temperature (°C) T: Operating temperature (°C) ΔT: Temperature increase at capacitor core (deg.)

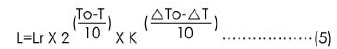

(2) The life equation based on the life with the rated ripple current applied under the maximum guaranteed temperature will be a conversion of the above equation (4), as below:

Lr: Life at the maximum guaranteed temperature with the rated ripple current (h)

ΔT0: Temperature increase at capacitor core, at the maximum guaranteed temperature (deg.)

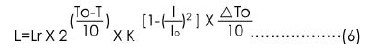

(3) The life equation considering the ambient temperature and the ripple current will be a conversion of the above equation (5), as below:

lo: Rated ripple current at the maximum guaranteed temperature (Arms)

I: Applied ripple current (Arms)

The life expectancy formula shall in principle be applied to the temperature range between the ambient temperature of +40°C and maximum allowable working temperature. The expected life time shall be about fifteen years at maximum as a guide in terms of deterioration of the sealant.